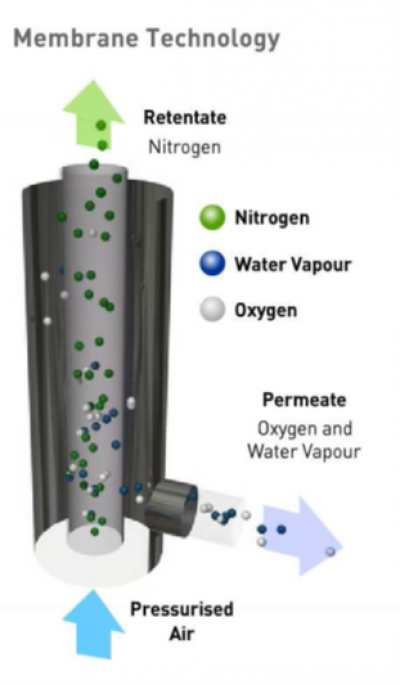

How Membrane Works

Available in a wide range of flow rates and purities. (Oxygen contents from 5% to less than 0.1%)

Dry compressed air is filtered and passed through the generator which contains hundreds of thousands of hollow fibres which separate the Nitrogen from the air through a process known as selective permeation.

Water vapour and oxygen rapidly permeate safely to the atmosphere, while the clean, pure, dry nitrogen gas is discharged under pressure into the distribution system. Pressure, flow rate and membrane size/quantity are the main variables that affect nitrogen production.

Nitrogen purity (oxygen content) is controlled by increasing/decreasing the speed of the flow through the membrane. At a given pressure and membrane size, increasing the nitrogen flow allows more oxygen to remain in the gas stream, lowering nitrogen purity. Conversely, decreasing nitrogen flow increases purity.

For a purity, higher air pressure to the membrane gives a higher nitrogen flow rate. Purity ranges of less than 90% to 99.9% are possible. By combining multiple membrane bundles, an infinite number of flow/purity ranges are available to satisfy practically any application that requires nitrogen gas.