How PSA Works

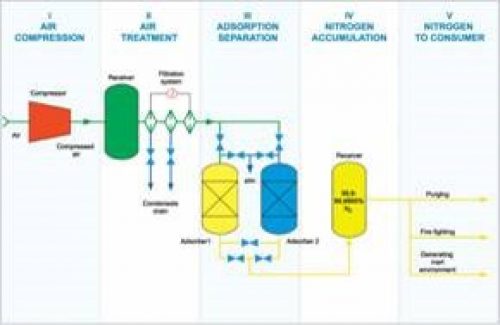

Probably the most common way of Nitrogen Generation is by the Pressure Swing Adsorption (PSA) principle to produce a continuous stream of nitrogen gas from compressed air. Two towers are filled with carbon molecular sieve (CMS). Pre-treated compressed air enters through the inlet manifold and flows up through the CMS to separate the compressed air.

Oxygen and other trace gasses are preferentially adsorbed allowing nitrogen to pass through. After a pre-set time, the on-line tower automatically switches to regenerative mode, during regeneration, the oxygen that has been collected in the CMS stage and the moisture that has been collected in the optional integrated dryer stage are exhausted to atmosphere.

A small portion of the outlet nitrogen gas is expanded into the bed to accelerate the regeneration process. Carbon molecular sieve differs from ordinary activated carbons in that it has a much narrower range of pore openings. This allows small molecules such as oxygen to penetrate the pores and be separated from nitrogen molecules which are too large to enter the CMS. The larger molecules of nitrogen by-pass the CMS and emerge as the product gas.